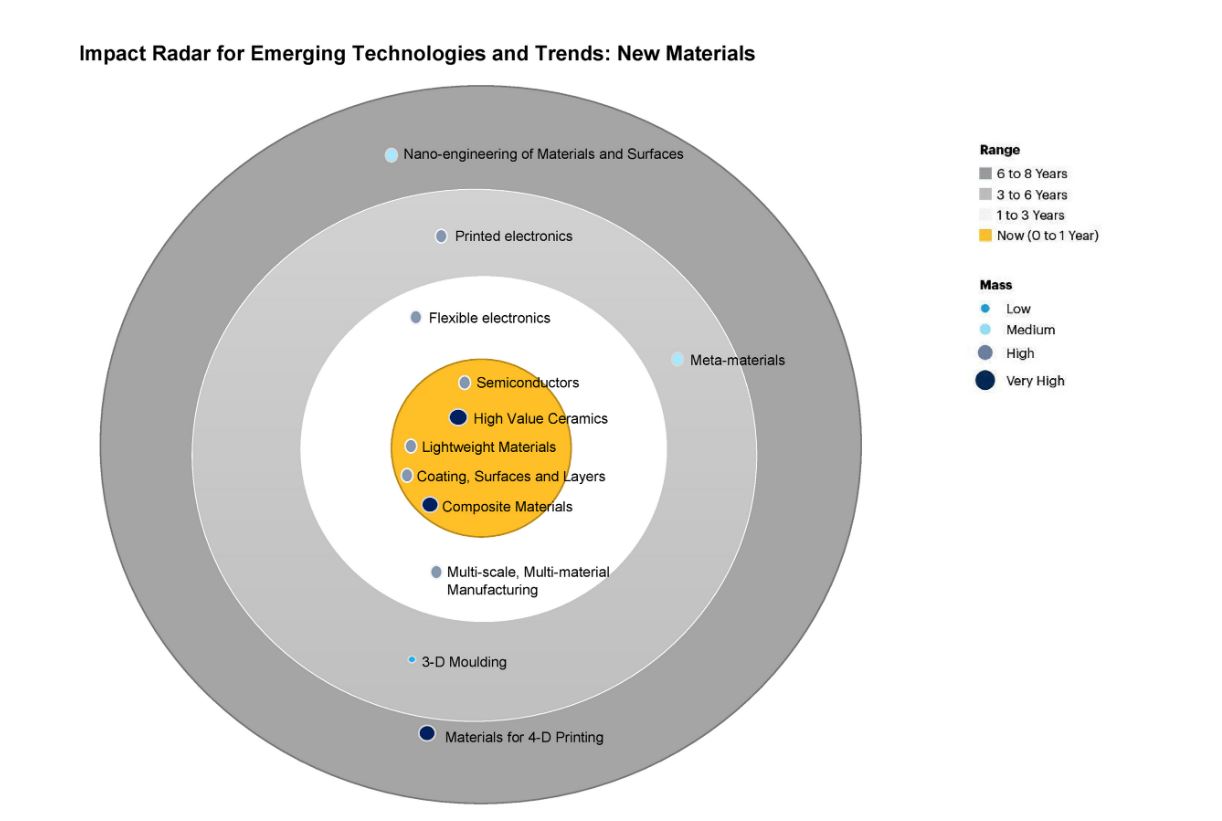

Tech radar

Smart materials are defined as materials that sense and react to environmental conditions or stimuli (e.g., mechanical, chemical, electrical, or magnetic signals). They offer a range of unique characteristics and have been used in a variety of products, ranging from household goods and novelty items to aviation, energy & construction sectors, automotive components and medical devices. They are the topic of extensive research and all manner of new applications will emerge in the future, reflecting both technological developments and a growing awareness of their capabilities.

From the past two decades, science and technology have made great improvements in synthesizing the new materials. They are divided mainly into four categories which are polymers, ceramics, metals, and smart materials. Among them, smart materials are becoming more popular because they have various applications as compared to standard materials. The special materials that can change their properties such as materials which can change its shape just by adding some heat or can change its phase instantly when placed near magnet are called smart materials.

Smart materials are also known as advanced materials or intelligent materials. They cannot be defined by a single specific definition. They can be defined as materials that can recoil their original shape to specific stimuli, or they can be defined as advanced materials that can respond smartly to environment changes. Smart materials are categorized on the basis of their properties such as active and passive, passive smart materials have ability to transfer a type of energy e.g. optical fibers are able to transfer electromagnetic waves. They are being developed for applications in numerous manufacturing sectors such as in the aerospace industry, biomedical industry, and general manufacturing industries.

Possible New Materials applications in the I4.0 and advanced manufacturing:

AUTOMOTIVE APPLICATIONS

In a modern passenger car there are several electromagnetic actuators for different functions, including comfort systems for the driver and passengers, actuators for engine control or vehicle control, servo- microactuators for power systems and aerodynamics. New approaches based on smart materials, instead of the traditional electromagnetic motors, can simplify in most cases the actuation, performing the same function with reduced size, weight and cost, optimising the movement and also offering the opportunity to implement new functions. The use of SM actuators as an alternative to electromagnetic motors for automotive applications, particularly for comfort purposes, shows some main advantages: smooth direct movement with high torque or force, no additional mechanism, noiseless operation and intrinsic reliability, since the motion is related to the physical properties of the material.

3D PRINTING FOR SOFT ROBOTICS

3D printing is an additive manufacturing (AM) process defined as the process of joining materials to make objects from 3D model data, usually layer upon layer, as opposed to subtractive manufacturing methodologies, such as traditional machining. 3D printing can deliver parts of very sophisticated and complex geometries with no need of post-processing, built from custom-made materials and composites with near-zero material waste, while being applicable to a diversity of materials, including smart materials such as shape memory polymers and other stimulus-responsive materials. One of the main example of the design freedom offered is that conventional assemblies can be restructured in a single complex structure that could not be manufactured with the current manufacturing processes. Another driver of the 3D printing technology is that it is environmentally and ecologically favourable. 3D printing technologies and methods are growing frequently in terms of application and market share, spreading into various manufacturing divisions, such as robotics, motorized, health and aerospace and are expected that this substantial growth will continue over the next few years.

3D printing has a limitation of speed and difficult scalability so currently the work on soft robotics is going on within the technological constraints of currently available 3D printers. 3D printing is a very slow process, but this is not a major issue, as no-one at this initial stage is looking for the mass production of soft robots. The high specificity and ability to print the most complex shapes makes 3D printing an extremely attractive choice for the fabrication of soft robots. However, one fundamental concern in using 3D printing technology for developing soft robots is that 3D printable soft materials have a large tendency to deform under the normally used forces during the building process due to their own weight so a support material becomes a necessity.

SMART GRID AND NANOTECHNOLOGIES: A SOLUTION FOR CLEAN AND SUSTAINABLE ENERGY

Smart materials have played significant contribution towards the energy sector and development of buildings.The challenge is to meet the demands of urbanization in an economically viable, socially inclusive, and environmentally sustainable fashion resulting with using materials and components with zero footprint. According to a World Energy Council study,3 global demand for primary energy is expected to increase by between 27% and 61% by 2050. Climate change is expected to lead to changes in a range of climatic variables, most notably temperature levels that will have impact on mterails used for prefabrication. Cyber-physical integration facilitates smart factories with high efficiency that are capable of fabricating high quality customized products.

The current barrier of mass production on location will be overcome with personal-and customized fabrication. Another popular trend aims at creating functional parts/machines in just a single step of fabrication. Due to the opportunities provided by the novel AM technologies, the design and production challenges are only restricted by the imaginations of the individuals.

Smart materials like Shape Memory Alloys (SMA), piezoelectric materials, Carbon Fiber Reinforced Polymer (CFRP), Shape Memory Polymer (SMP) etc. are the materials that make up the backbone for latest aerospace and automotive application.

Source: Gartner Top Strategic Technology Trends for 2022

Future of smart materials:

Trends 2022

The global market for smart materials will grow rapidly, since it will be the market for the whole supply chain. It will have important impact on multisectorial markets as aviation, automotive, construction, medical into the several areas where smart materials are used, including implant material, sensors and actuators, structural materials, shape memory, smart fluid, alloys, as well as by type of material.

Shape memory alloy based on nickel, copper, titanium, aluminium and a few others. Advances in metallurgy and computer analyses and design of alloys has opened the door to an unlimited class of materials, where computer is used to explore the potential characteristics of an alloy before it is manufactured.

4D printing is one of the innovative technologies that creates notable innovations in the medical field. It merges multi-material 3D printing and the combination of smart materials into the printable material to develop an exciting new technology called 4D printing, having a structure that can modify its shape, memorise the shape and return to it after deformation. For the COVID-19 pandemic, this technology proves to be useful in the manufacturing of smart medical parts, which helps treat infected patients.

As compared to 3D printing, 4D printing adds time as an additional element in the manufactured part. 4D printing uses smart materials with the same printing processes as being used in 3D printing technology, but here the part printed with smart materials change their shape with time or by the change of environmental temperature, which further creates innovation for patient treatments.

4D printing manufactures a given part, layer by layer, by taking input of a virtual (CAD) model and uses smart material. This paper studies the capability of smart materials and their advancements when used in 4D printing.

New industries are rapidly introducing smart materials to tailor and optimize the production.

Contact

Krakow Technology Park sp. z o.o.

ul. Podole 60

30-394 Kraków, Poland