Metal ADditivE for LOmbardy (MADE4LO)

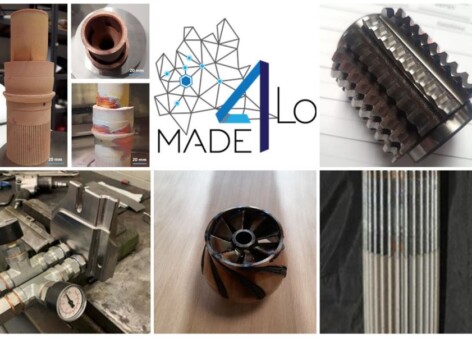

Concerning Additive Manufacturing for metals, a “widespread” factory for the development of metal 3D printing technology was the objective of the project Metal ADditivE for LOmbardy (MADE4LO), with the involvement of two Universities (Politecnico di Milano and Università di Pavia), three Big Industries (Tenova, BLM, and GF Machining Solutions), and six SMEs (TTM Laser, 3D-NT, GFM, Fubri, Co. Stamp, and Officine Meccaniche G. Lafranconi). The project has addressed and proposed innovative solutions to the main technological challenges of additive manufacturing, such as: production of new metal powders, printing of complex materials, large and multi-material and the adoption of hybrid processes that include both additive and subtractive aspects. It also contributed to the creation of two regional and national competence centres dedicated to AM; GFM has founded, in collaboration with other industrial realities, the Additive Technology Centre – ATC, while GF Machining Solution has established a competence centre where additive printing is combined with traditional technologies. Several innovative applications such as:

- printing of pure copper components,

- difficult materials with high performance in terms of hardness,

- production of large, multi-material, geometrically complex components with a

hybrid machining component, - realization of a large and multi-material recuperator,

- creation of a mould with additive and subtractive hybrid process,

realization of an Axial Vorticator for Gas Turbines

Contact

Krakow Technology Park sp. z o.o.

ul. Podole 60

30-394 Kraków, Poland